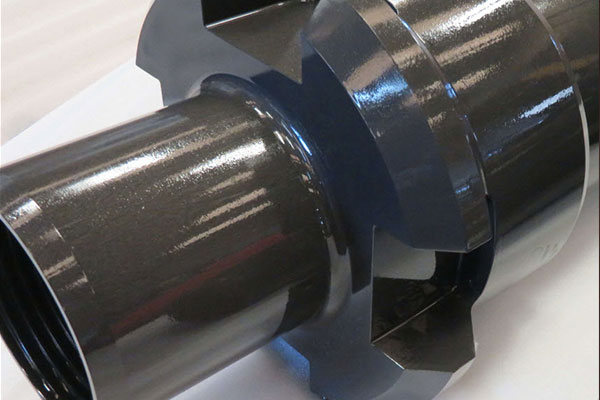

Non metallic coating like Phosphate coatings are a crystalline conversion coating for steel and other metals that is formed on a ferrous metal substrate. The process of Phosphate coating is employed for the purpose of pretreatment prior to coating or painting, increasing corrosion protection and improving friction properties of sliding components. In other instances, phosphate coatings are applied to threaded parts and top coated with oil (P&O) to add anti-galling and rust inhibiting characteristics. The phosphating process relies on the basic pickling reaction that occurs on the metal substrate when the process solution comes in contact with the metal. The main benefits that phosphating provides is strong adhesion and corrosion protection. Typically, phosphate coatings are applied to steel parts because iron in the steel is required for the coating to form. Manan Heat Treatment offers both zinc phosphate and manganese phosphate coating in a dark gray/black aprearance.

- Non metallic coating

- Phosphating

- Chromating

- Blacking